- Description

Description:

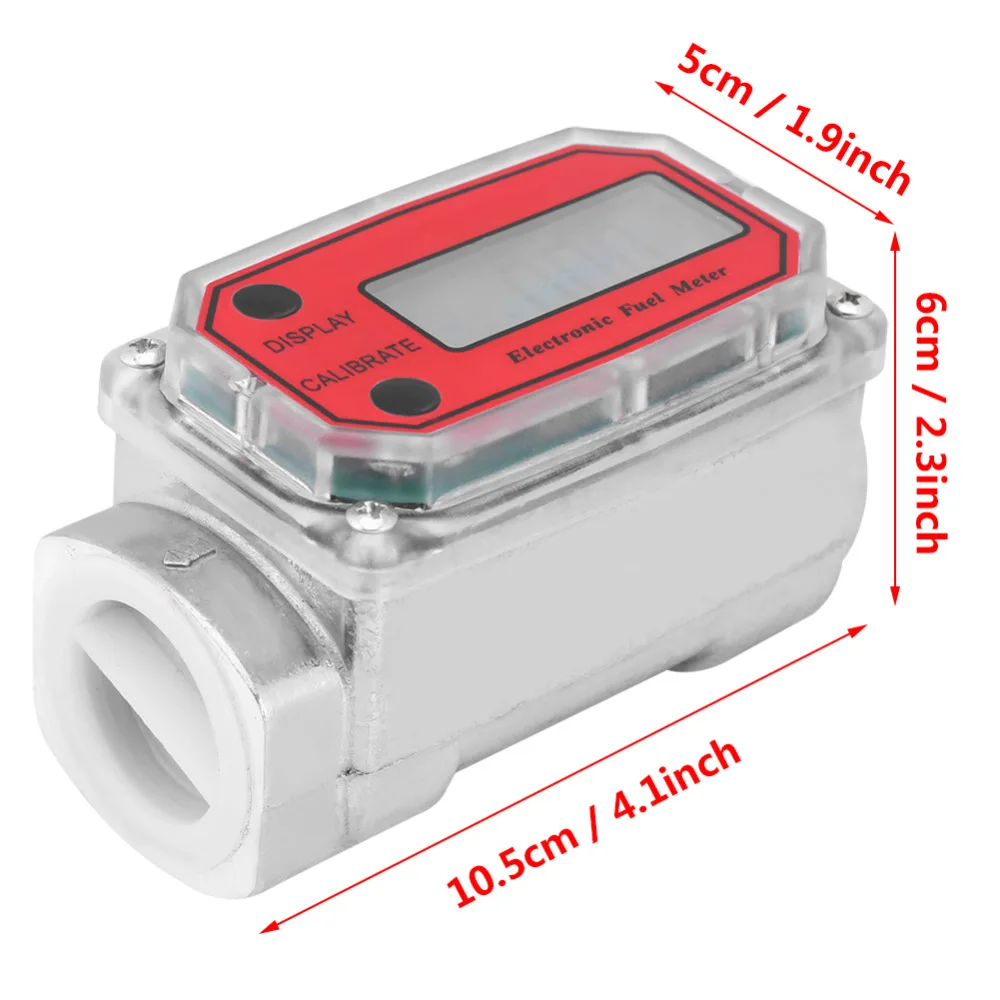

This digital turbine flow meter has modular design, high accuracy, compact size and stable performance. Easy to replace and maintain internal components. Suitable for use with output modules, sensors and remote transmitters.

Features:

- Modular design makes it suitable for use with output modules, sensors and remote transmitters.

- Compact structure, easy to install.

- Intuitive clear reading, high reliability, measuring accuracy is ±1%.

- High-definition displays show both instantaneous and cumulative flow.

- Can be widely used to measure diesel, kerosene, gasoline, etc.

Specification:

Operating voltage: 2.3-3.3V

Battery type: 2 x AAA LRO3 batteries

Thread size: 1inch NPT

Repetition: ±0.5%

Measure accuracy: ±1%

Maximum working pressure: 20BAR

Flow range: 15-120L / Min

Single count: 0.00-9999.9

Total cumulative count: 0-99999

Mistakes count: 0.1000-9.9999

Working temperature: -10°C ~ +60°C(14°F~140°F)

Standby time: 1 year

Application: Diesel, kerosene, gasoline

Color: Red, Blue(Optional)

Weight: 371g

Malfunction and solution:

| The flow meter is not accurate. | 1. The method of field calibration is not correct. | Calibrate again. |

| 2. The flow rate on the meter is below the lowest. | Increase the flow rate. | |

| 3. The flow meter is blocked by the dry liquid. | Take out the impeller and clean it carefully and make sure the impeller turns freely. | |

| 4. The impeller is wrapped by the sealing material. | Remove the meter and make sure the impeller turns freely. | |

| 5. Too close to the impeller. | Install properly. | |

| 6. Too close to the motor or electronic noise environment | Install properly. | |

| The reading numbers faded or blanked out. | 1.Battery is exhausted or not connected | Check the batteries or even replace them. |

| Flow rate is normal but the meter can not count. Press the button of DISPLAY, the meter starts. | 1. Field calibration is not correct. | Calibrate again. |

| 2. The impeller is blocked or damaged. | Remove the meter and make sure the impeller turns freely. | |

| 3.The impeller is wrapped by the sealing material. | Remove the meter and make sure the impeller turns freely. | |

| Flow rate is low and the meter can not count. Press the button of DISPLAY, the meter starts. | 1. The flow meter is blocked by the dry liquid. | Take out the impeller, clean it carefully and make sure the impeller turns freely. |

| 2. The flow rate on the meter is below the lowest. | Increase the flow rate. | |

| The meter can not calibrate. | 1. Circuit board is break down. | Replace the circuit board. |

| 2. Button is fail to press. | Replace the circuit board. |

Package List:

1 x Turbine Flow meter

PS: We have two colors, Red and Blue. Please note!! Or color is random!!!

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD CHF

CHF HKD

HKD JPY

JPY RUB

RUB BRL

BRL CLP

CLP NOK

NOK DKK

DKK SEK

SEK KRW

KRW ILS

ILS MXN

MXN CNY

CNY SAR

SAR SGD

SGD NZD

NZD ARS

ARS INR

INR COP

COP AED

AED