- Description

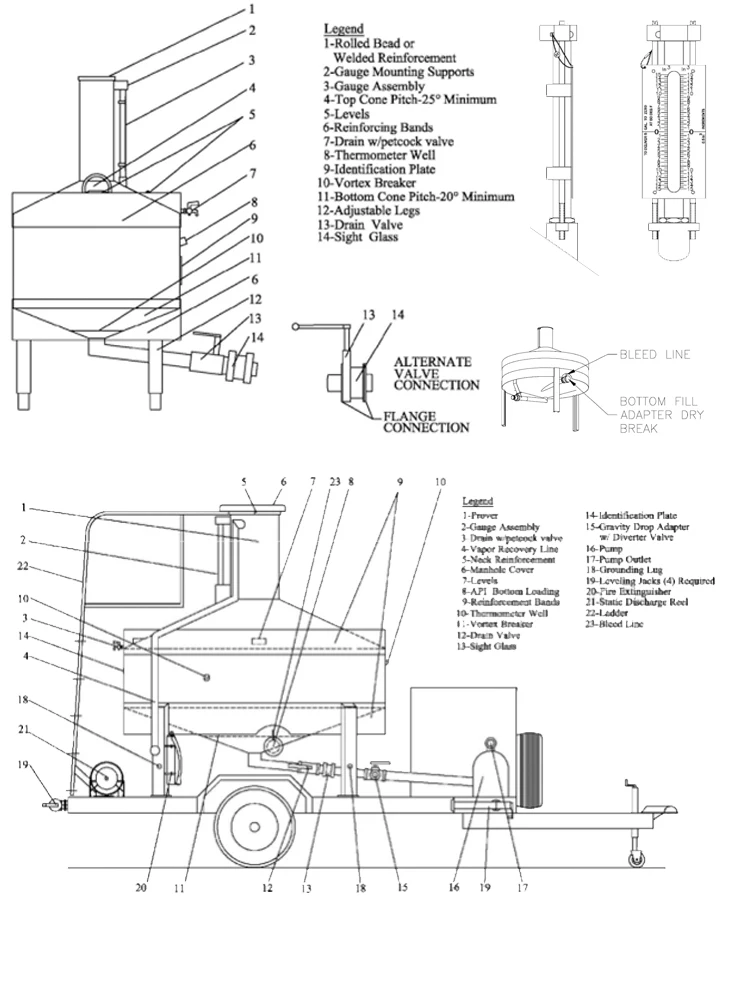

· AISTAR -Calibrated Measures & Volumetric Provers

· Built to NIST Handbook 105-3 Standards, OIML R-120 and API Manual of Petroleum Measurement Chapter 4

· Manufactured of Series 304 Stainless Steel, which resists ordinary rusting, can be easily cleaned, resists organic chemicals, no slag and requires no internal coating. Series 316 stainless steel is available upon request

· Calibration By Standards Traceable to National Institute of Standards and Technology

· Graduated Neck with scale that is sealed

· A butterfly valve is standard with the drain at the center point. This is the most versatile unit for use in the field whether emptying into tank, using a pump or gravity discharge. A ball valve is optional. It is used mostly in laboratory applications or where special application exists. The drain would then proceed at a 7 degree decline with the ball valve near the perimeter of the prover

· Reinforcing bands to prevent distortion of prover when full with liquid and when being transported

· Two spirit levels with seals are used as level indicators for provers more than 18” diameter, otherwise a circular bulls- eye level is installed.

· Two Lifting Loops are attached to top band of prover

· Standard capacities are available from 5 Gallon/20 Liter to 1500 Gallon / 5000 Liter. Call for special volumes.

· All Stainless Steel Provers

· Steel or Aluminum skid

· Three Bolt down - Adjustable Crank Legs to level prover

· Stainless Steel hinged locking cover for top of neck

· Another cover is extended to protect the Gauge Glass from accidental breakage and can be secured with a lock for safety.

· Sight flow indicator for ob- serving fluid flow down- stream of the shut-off valve.

Specifications:

|

NOMINAL CAPACITY |

100LITER-CALIBRATED”TO DELIVER” AT 15 DEG C |

|

MATERIA |

TYPE 304&316 STAINLESS STEEL |

|

DRAIN VALVE |

CENTER DRAIN,2 INCH BUTTERFLY VALVE |

|

DESIGN |

REINFORCING BANDS TO PREVENT DISTORTION OF PROVER WHEN FULL WITH LIQUID AND WHEN BEING TRANSPORTED |

|

TEMPERATURE MEASUREMENT |

STAINLESS STEEL THERMOMETER WELL LOCATED SO THAT CLOSED END IS AT THE APPROXIMATE CENTER OF THE PROVER |

|

VOLUME INDICATION |

ALUMINUM GRADUATED SCALE |

|

REQUIRED SCALE RANGE |

MILLILITER MINOR GRADUATIONS |

|

TOLERANCE |

0.02% SCALE ACCURACY |

|

DATA PLATE |

ENGRAVED BRASS |

|

GAUGE GLASS FITTING |

STAINLESS STEEL |

|

LIFTING LOOPS |

LIFTING LOOP ATTACHED TO TOP BAND OF PROVER |

|

SIGHT FLOW INDICATOR |

INSTALLEN BETWEEN PROVER DRAIN VALVE AND LEVELING BALL JOINT TO ENSURE DRAIN TIME MEETS NIST (30 SECONDS AFTER MAIN FLOW CESSATION )DRAIN REQUIREMENTS.ALSO USED TO CHECK DRAIN VALVE FOR LEAKAGE. |

|

FILL |

STAINLESS STEEL “TOP LODADING-SUBMERGED FILL”PIPE PASSES THROUGH THE UPPER CONE AND EXTENDS TO THE BOTTOM CONE,REDUCING FOAMING WHILE FILLING |

|

NECK COVER |

STAINLESS STEEL HINGED LOCKING COVER FOR TOP OF NECK TO PREVENT CONTAMINATION OR DAMAGE DURING TRANSPORTATION.ANOTHER COVER PROTECTS THE GAUGE GLASS FROM ACCIDENTAL BREAKAGE AND CAN BE SECURED WITH A LOCK FOR SAFETY. |

|

CRANK LEGS |

ADJUSTABLE BOLT DOWN LEGS FOR LEVELING PROVER.ADJUSTMENTS ARE MADE BY CRANK HANDLES ON EACHLEG |

The temperature at which test measures and provers are referenced during calibration and during

use for testing petroleum products is generally 15.56 °C (60 °F). International standards

reference petroleum products to 15 °C. Provers may be used for applications other than

petroleum products or in areas where a different reference temperature is used for petroleum

products. In such cases, the appropriate reference temperature for the application should be

identified and used. For example, the reference temperature for provers used in testing milk is

4.44 °C (40 °F).

1000L proving tank details

|

|

Principle |

Measuring fuel density at a fixed volume of 20 ° C water density as standard |

|

Type |

bracket type |

|

|

Function |

Test the standard of gas station flowmeter |

|

|

Liters |

1000L |

|

|

Size |

180*180*230cm |

|

|

Material |

SS 304 |

|

|

Weight |

450KG |

|

|

Accuracy |

0.05%, 0.001%, 0.0002% |

|

|

Ruler type |

Scale, Vernier caliper |

|

|

Ruler |

scale 1000ML |

|

|

Packaging |

Iron frame + carton packaging |

1500Liter stainless steel prover specifications

1. Construction

Built to N.I.S.T handbook 105-3 standards and API Manual of petroleum measurement standards chapter 4

2 . Calibration

Factory certified using standards traceable to national institute f standards and technology .

3 . Nominal capacity

1500 Litter - caubrated “to deliverd” at 15 DEG C

4 . Nominal diameter

50 inch

5 . Nominal height

80 inch

6 . Prover weight(DRY)

1000 LB

7 . Meterial

TYPE 304 STAINLESS STEEL

8 . Drain valve

Center drain, 3inch butterfly valve

9 . Desing

Reinforcing bands to prevent distortion of prove when full with liquid and when being transported .

10 . Temperature measurement

Stainless steel thermometer walls,one near top of body, one in the middle of the body and one near bottome of body.

11 . Level indication

Spirit levels located 90 deg from one another

12 . Volume indication

Aluminum graduated scale

13 . Scale graduations

250 ML Increments

14 . Required scale range

±11250 Mlliters . The gauge scale shall be graduated both above and below the nominal capacity graduation by an amount not less than 1% of the prover volume.

15 . Tolerance

0.05% Scale accuracy

16. Data plate

Engraved brass

17 . Gauge glass fitting

STAINLESS STEEL

18 . Lifting loops

Lifting loops attached to top band of prover

19 . Sight flow indicator

Installed between prover drain valve and leveling ball joint to ensure drain time meets nist (30second after main flow cessation ) drain requirements. Also used to check drain valve for leakage.

Stainless steel “Top loading-submerged fill ” pipe passes through the upper cone and extends to the bottom cone, reducing foaming while filling.

21 . Neck cover

Stainless steel hinged locking cover for of neck to prevent contamination or damage during transportation transportation . Another cover protects the gauge glass from accidental breakage.

22 . Legs

Non - adjustable bolt down legs.

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD CHF

CHF HKD

HKD JPY

JPY RUB

RUB BRL

BRL CLP

CLP NOK

NOK DKK

DKK SEK

SEK KRW

KRW ILS

ILS MXN

MXN CNY

CNY SAR

SAR SGD

SGD NZD

NZD ARS

ARS INR

INR COP

COP AED

AED