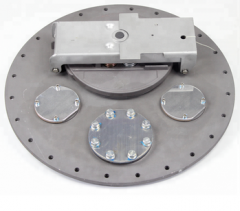

- Description

Fuel tanker sensor Explosion-Proof Anti-overflow probe with CNEX flag

Anti- overflow probe is mainly used in the tanker, tank material add conditions, when charging excessive internal signal transmission terminal, and prompted the installation platform to stop charging, so as to ensure the safety of the installation.

The anti-overflow probe and the overflow socket and the earth stud together form an antisemitic system.

The anti-overflow probe is used for tank trucks, tank trucks, and the like. Made of high-quality aluminum, high-quality materials, durable and long service life. Strong anti-interference ability, free from external influences, high reliability, anti-overflow, anti-static, high-quality workmanship, can effectively prevent liquid overflow, and ensure that the electrostatic grounding resistance meets the safety standards.

The anti-overflow probe produced by the company has excellent craftsmanship, anti-overflow and anti-static, novel style, easy installation, stable quality, longer temperature resistance and longer service life. Survive by quality and service as the center.

The anti-overflow anti-static sensor is designed for bottom-filled tank trucks to prevent liquid spillage while protecting

The electrostatic grounding resistance of the certificate complies with the safety standards and constitutes a vehicle anti-overflow anti-static sensing system. Through standard wiring sockets and plugs

Realize the docking between the tanker and the oil depot system, and support the anti-overflow anti-static control system of the oil depot to ensure the safety during the bottom filling process.

All and environmentally friendly.

Among them, the anti-overflow anti-static sensor has three parts:

FE-BLS anti-overflow probe, FE-C wiring socket, FE-D grounding bolt.

The FE-BLS anti-overflow probe uses optical principles to detect the level of liquid in the tank of the tank. Installed in the car with FE-C wiring socket

The connection provides a liquid level status signal to the oil depot overflow control system to achieve interlock control with the fuel delivery system.

Technical Parameters

1. Working voltage: intrinsically safe voltage 5 ~ 15VDC

2. Working current: <5mA

3. Working temperature: -40 ° C ~ 60 ° C

4. Response time: <1s

5. Explosion-proof grade: ExiaIIBT4

Maintenance

1. Remove all bolt and bolt parts to maintain;

2. Remove and assemble without special tools.

Features:

Designed for bottom fuel delivery system, in line with API standards;

Integrated intrinsic safety design of anti-overflow probe, especially suitable for use in flammable, explosive and other dangerous occasions;

Full digital circuit design, strong anti-interference ability, Wide application voltage range, high reliability;

Anti-overflow probe detection liquid level can be adjusted, the maximum adjustable range is 50mm;

The shell is made of integral die-cast aluminum alloy, explosion-proof, anti-corrosion, especially suitable for flammable and easy Use of loading and unloading sites for explosive liquid petrochemicals;

Functional features

1. Optical principle, integral design;

2. The installation and adjustment is convenient, and the alarm height can be adjusted by locking the positioning device.

3. Wide input voltage range, full digital circuit design, strong anti-interference ability;

4. The built-in shaft parts all adopt stainless steel material to ensure its corrosion resistance.

Guideline The FE-BLS anti-overflow anti-static sensor has been inspected by the National Instrument and Explosion Safety Supervision and Inspection Station (NEPSI).

Column criteria:

GB3836.1-2000 "Electrical equipment for explosive gas atmospheres - Part 1: General requirements"

GB3836.4-2000 "Electrical equipment for explosive gas atmospheres - Part 4: Intrinsically safe "i""

The product explosion-proof mark is ExiaIIBT4.

The ambient temperature of the product is between -40 ° C and +60 ° C.

| Product Name | Fuel tanker sensor Explosion-Proof Anti-overflow probe with CNEX flag |

| Material | Aluminum alloy |

| Rate voltage | 12V DC |

| Rate current | 200mA |

| Pi | 0.75W |

| CNEX flag | Ex ia IIB T4 Ga |

| CNEX NO | CNEX16.3848X |

| Used | when charging excessive internal signal transmission terminal, and prompted the installation platform to stop charging, so as to ensure the safety of the installation. |

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD CHF

CHF HKD

HKD JPY

JPY RUB

RUB BRL

BRL CLP

CLP NOK

NOK DKK

DKK SEK

SEK KRW

KRW ILS

ILS MXN

MXN CNY

CNY SAR

SAR SGD

SGD NZD

NZD ARS

ARS INR

INR COP

COP AED

AED