- Description

Materials

- Top: Cast iron

- Body: Cast iron

- Disc: M-19

- Carrier: Zinc-plated steel

- Stem: Copper-nickel-chrome-plated brass

- Poppet spring: Stainless steel

- Seal: M-19 O-ring

- Packing Nut: Brass, Teflon®-coated

- Inlet and outlet thread: 1 1/2" (4 cm) NPT (British threads available)

- With black Duragard® E-coating

Features

- High Flow Capacity – The primary poppet is held out of the flow stream while the secondary poppet is held normally open to minimize head loss across the valve and to protect the poppet seals from damage and erosion. True 1-1/2" (4 cm) and 2" (5 cm) body sizes ensure maximum flow.

- Fire Protection – A fusible link trips the valve closed at 165° F to shut off fuel supply to the dispenser.

- Main Poppet Seat Integral to the Top Assembly – Having the main poppet seat as an integral part of the valve top assures a new, clean seating surface is installed each time the top is replaced. This design also ensures that the integrity of the seal between the valve top and bottom is verified during line testing and allows full inspection of the main poppet when the top is removed.

- Duragard®-Coat Finish – Provides superior corrosion resistance.

- Reliable Shut-off – A stainless steel main spring, a Teflon®-coated brass packing nut, and a copper/nickel/ chrome-plated brass stem are designed to prevent tar build-up and corrosion from interfering with poppet operation after long periods of normal service without activation.

- Integral Test Port – A 3/8" (9.5 mm) Test Port allows the piping system to be air-tested without breaking any piping connections.

- Patented Thermal Relief Valve – Relieves excessive pressure over 25 psi caused by thermal expansion of fuel in the dispenser piping system in the event of fire (double-poppet models only).

- Low-Profile Tops – Female and Union-top double-poppet valves have a low-profile top to allow upgrading from OPW single-poppet valves without changing existing piping.

- Multiple Mounting Options – Valves are boss-mounted to stabilizer bars in sumps and pans or mounted to bars embedded in the island with optional U-Bolt kits 10UBK-015 (not included). Versatile Combination Body (boss mount/U-Bolt mount) models are available to accommodate most mounting applications with one valve style.

- Underwriters Laboratories – Listed for use with gasoline and 85% and 100% methanol. All OPW 10 Emergency Shut-Off Valves meet requirements of UL STANDARD 842.

- Compatible with 85% ethanol (E85)

Listings & Certifications

Ordering Specifications

Female Threaded Top (Outlet) Connection Valves

| Model No. | Body Size | Connection Threads | Poppet Configuration | Application | Replacement Top | |

| in. | cm | |||||

| 10BF-5725 | 1-1/2 | 4 | NPT | Single | Pressure | 10RFT-5750 |

| 10BFP-5726 | 1-1/2 | 4 | NPT | Double | Pressure | 10FTP-5701 |

| 10RF-2001 | 2 | 5 | NPT | Single | Pressure | 10RFT-5742 |

| 10RFP-2002 | 2 | 5 | NPT | Double | Pressure | 10RFTP-5752 |

Male Threaded-Top (Outlet) Connection Valves

| Model No. | Body Size | Connection Threads | Poppet Configuration | Application | Replacement Top | |

| in. | cm | |||||

| 10BM-5825 | 1-1/2 | 4 | NPT | Single | Pressure | 10RMT-5850 |

| 10BHMP-5830 | 1-1/2 | 4 | NPT | Double | Pressure | 10RMTP-5851 |

| 10SBHMP-5830 | 1-1/2 | 4 | NPT | Double | Suction | 10SHMTP-5811 |

| 10RM-2003 | 2 | 5 | NPT | Single | Pressure | 10RMT-5842 |

| 10RMP-2004 | 2 | 5 | NPT | Double | Pressure | 10RMTP-5852 |

Union-Top (Outlet) Connection Valves

| Model No. | Body Size | Connection Threads | Poppet Configuration | Application | Replacement Top | |

| in. | cm | |||||

| 10BU-5925 | 1-1/2 | 4 | NPT | Single | Pressure | 10RUTC-5975 |

| 10BUP-5926 | 1-1/2 | 4 | NPT | Double | Pressure | 10UTCP-5901 |

| 10SBUP-5926 | 1-1/2 | 4 | NPT | Double | Suction | 10SUTCP-5911 |

| 10RU-2005 | 2 | 5 | NPT | Single | Pressure | 10RUTC-5962 |

| 10RUP-2006 | 2 | 5 | NPT | Double | Pressure | 10RUTCP-5972 |

| Note: All BSPP Thread Shear Valves must be ordered through OPW's Europe or Asia office. | ||||||

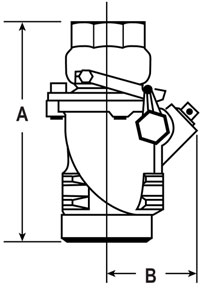

Dimensions

1-1/2" Dimensions

| 10BF | 10BFP | 10BM | 10BHMP | 10BU | 10BUP | |||||||

| 10SBFP | 10SBHMP | 10SBUP | ||||||||||

| in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | |

| A | 6-21/64 | 161 | 6-21/64 | 161 | 6-13/16 | 173 | 7-11/16 | 195 | 7-1/4 | 184 | 7-1/4 | 184 |

| B | 2-3/4 | 70 | 2-3/4 | 70 | 2-3/4 | 70 | 2-3/4 | 70 | 2-3/4 | 70 | 2-3/4 | 70 |

| C | 2-11/16 | 69 | 2-11/16 | 69 | 2-11/16 | 69 | 2-11/16 | 69 | 2-11/16 | 69 | 2-11/16 | 69 |

| D | 1-3/4 | 44 | 1-3/4 | 44 | 2-1/4 | 57 | 3-1/8 | 79 | 2-11/16 | 69 | 2-11/16 | 69 |

2" Dimensions

| 10RF | 10RM | 10RU | 10RFP | 10RMP | 10RUP | |||||||

| 10RFS | 10RMS | 10RUS | 10RFSP | 10RMSP | 10RUSP | |||||||

| in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | |

| A | 8-3/8 | 213 | 9-27/32 | 250 | 9-13/32 | 239 | 8-3/8 | 213 | 9-27/32 | 250 | 9-13/32 | 239 |

| B | 3-7/64 | 79 | 3-7/64 | 79 | 3-7/64 | 79 | 3-7/64 | 79 | 3-7/64 | 79 | 3-7/64 | 79 |

| C | 3-1/4 | 83 | 3-1/4 | 83 | 3-1/4 | 83 | 3-1/4 | 83 | 3-1/4 | 83 | 3-1/4 | 83 |

| D | 3-1/16 | 78 | 4-9/16 | 116 | 3-7/8 | 98 | 3-1/16 | 78 | 4-9/16 | 116 | 3-7/8 | 98 |

PA15 Offset Adaptor

The PA15 Offset Adaptor is designed for adjusting misalignment of pipe in dispenser sumps and suction stubs. The PA15 has a low profile feature, and is designed for maximum flow.

Replacement Valve Tops

| Model No. | Body Size | Connection Threads | Poppet Configuration | Application | Top Connection | Profile | |

| in. | cm | ||||||

| 10RFT-5750 | 1-1/2 | 4 | NPT | Single | Pressure | Female | |

| 10RFTP-5751 | 1-1/2 | 4 | NPT | Double | Pressure | Female | |

| 10FTP-5701 | 1-1/2 | 4 | NPT | Double | Pressure | Female | Low Profile |

| 10RMT-5850 | 1-1/2 | 4 | NPT | Single | Pressure | Male | |

| 10RMTP-5851 | 1-1/2 | 4 | NPT | Double | Pressure | Male | |

| 10SHMTP-5811 | 1-1/2 | 4 | NPT | Double | Suction | Male | |

| 10RUTC-5975 | 1-1/2 | 4 | NPT | Single | Pressure | Complete Union | |

| 10UTCP-5901 | 1-1/2 | 4 | NPT | Double | Pressure | Complete Union | Low Profile |

| 10RFT-5742 | 2 | 4 | NPT | Single | Pressure | Female | |

| 10RFTP-5752 | 2 | 5 | NPT | Double | Pressure | Female | |

| 10RMT-5842 | 2 | 5 | NPT | Single | Pressure | Male | |

| 10RMTP-5852 | 2 | 5 | NPT | Double | Pressure | Male | |

| 10RUTC-5962 | 2 | 5 | NPT | Single | Pressure | Complete Union | |

| 10RUTCP-5972 | 2 | 5 | NPT | Double | Pressure | Complete Union | |

Other Replacement Parts

| Part Number | Description |

| 202950 | Tetra Seal |

| H11361M | 2" Tetra Seal |

| H07659M | Link Spring |

| H07643RB | Link Retaining Screw |

| H04788M | Hold-Open Link (Brass) |

| H05361 | Safety Hub S/A-Fusible Link |

| 10UBK-015 | U-Bolt Kit for 1-1/2" |

| 10UBK-020 | U-Bolt Kit for 2" |

Important Notice

When mounting the OPW 10 Series Emergency Shut-off Valves, the anchoring system employed must withstand a force greater than 650 ft. pounds per valve. NFPA Code 30A, Automotive and Marine Service Station Code, requires that the automatic closing feature of emergency shut-off valves be checked at least once per year by manually tripping the hold-open linkage. OPW recommends the use of PISCES® Stabilizer Bar Support System for proper mounting of 10 Series Valves.

Notice

As per NFPA 30A, electrical supply to the submersible pump must always be disconnected before servicing meters, dispensers or emergency shut-off valves.

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD CHF

CHF HKD

HKD JPY

JPY RUB

RUB BRL

BRL CLP

CLP NOK

NOK DKK

DKK SEK

SEK KRW

KRW ILS

ILS MXN

MXN CNY

CNY SAR

SAR SGD

SGD NZD

NZD ARS

ARS INR

INR COP

COP AED

AED