- Description

Configuration and condition

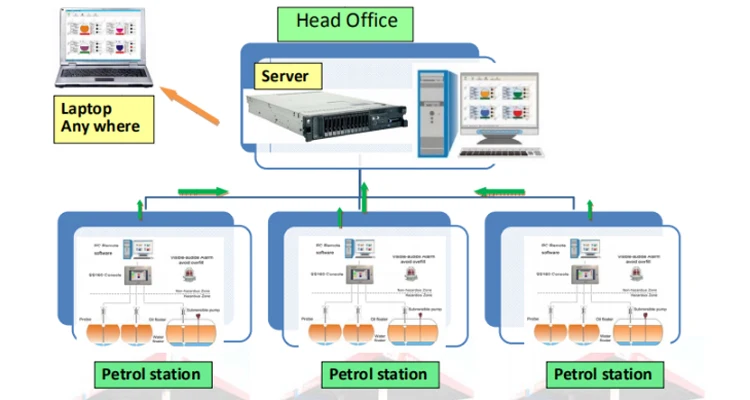

1. Petrol stations

There should be internet connection in petrol stations.

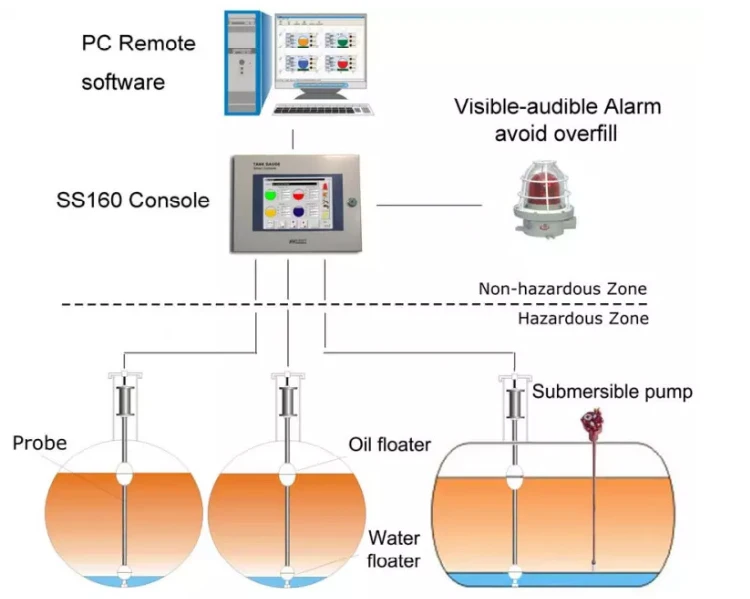

Have computer in stations, and equipped with SP300 probe, SS160 console, PC Remote software 200 Safety device: Audible-visible Alarm can protect against over fill when loading oil into underground tank from tank truck

2. Head office

Fixed IP address is necessary.

Server, common model is ok.

3. Software - Socket service software and database.

4. Laptop terminalIn any where, any time, just have internet, you can see all your tanks status by our Golden Assistant Software.

Working principle

SP probes are installed in fuel tanks, the motherboard in probe head send signals to product floater and water floater in highly frequency, usually milliseconds, and floater responds and feedback to motherboard of probe.

By RWP4x0.5 shielding cable connection, SS console asks the tanks information (oil product level, water level and temperature) from SP probes in milliseconds, too. One important feature of SS console is that users can input tank volume chart into program, SS console program will automatically simulate a precisely tank module and calculate the stock volume base on measured oil height, water height and temperature value.

SS console connects to site computer by RS232, PC Remote back-office software which installed at site computer will asks tanks information from SS console in milliseconds frequency, so users can monitor tanks information from PC screen.

Base on internet connection between sites and head office, Server in head office can received the tanks information transferred from PC Remote back-office software, and store every record for inquiry in future.

More we can do for you is that when you travel or at home, it is easy to see the current conditions of each tank, just have internet and a computer or notebook which preinstalled Inquiry software GAS-01.

(Data format IP Date Packet, Encrypted by DES)

How can we do if there no internet at site or it is oil tank4ruckor?

SS ce, will send tank information like oil height, oil stock, water height and temperature of each tank to the head office; There another GSM module which receive the short message from each site, and saved at Central management system for inquiry and analysis.

Features and Benefits

-Authorities for access to operate console, high grade of management and control

-Large expansion ability for future needs, more sites share the same one head office software, save cost

-History records for inquiry and analysis

-High precision data with 0.05mm accuracy

-Real time monitoring offer the most safe and efficient management

-Support shift duties and automatically creates duty report after shift

-Support export history records to.xls, text, or PDF format for record

-Support Built-in printer for reports print (option)

-Audible and visible ex-proof alarm perfectly protect tank against over fill when loading from tank truck

| 1-6 tanks | 1 console | 1-6probe according to the tanks |

| 7-12 tanks | 1 updated console | 7-12probe according to the tanks |

| CNG tanks | 1 console |

Probe for CNG tanks |

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD CHF

CHF HKD

HKD JPY

JPY RUB

RUB BRL

BRL CLP

CLP NOK

NOK DKK

DKK SEK

SEK KRW

KRW ILS

ILS MXN

MXN CNY

CNY SAR

SAR SGD

SGD NZD

NZD ARS

ARS INR

INR COP

COP AED

AED