- Description

Tanker trailer parts 4" Aluminum Manual Bottom Loading Valve

Product Introduction:

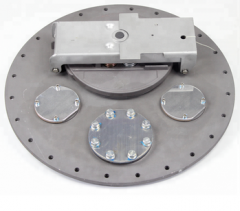

Pneumatic Bottom Valve Tank Bottom Seat Valve ,is installed on the bottom of oil tank to transfer the liquid from bottom to tank with advantage of easy operation,saving time,safe.

Size:4" Material:Aluminum

High Flow,lower pressure lost

Shear Groove,automatic cut-off and leak proof under emergency condition.

Shear Valve,using automatic piston right and durable spring. After emergency cutoff,it can still keep hermetic like before.

Emergency,if there is no air source or open failure for other reason,it can be also opened manually without demolition.

Special surface Treatment

Aluminum alloy surface is treated by oxidation to improve the anticorrosion.

Hydrodynamic Body

Design and high lift poppet minimizes pressure drop to give maximum flow rate.

External Shear Groove

When in the event of accidental damage,the external housing will break away from the self-cut groove,keeping the connection to the valve tank mounting flange,leaving the bottom valve sealing mechanism within the tank compartment intace,ensuring the tightness of tank.

Two Ways-Operation

Can install the external air cylinder to do pneumatic control if necessary.

Manual Tanker Emergency Shut off Valve

Aluminum Bottom Valve (Emergency Shut off Valve) is installed on the bottom of the tanker, the top parts is tightly sealed inside the tanker. External shear groove design limits product spillage when the tanker is crashed down,it will automatically cut off itself via this groove under the situation there's no affection on the sealing. This will efficiently protect the over rolled tanker from leakage to ensure the safety when transportation. This product is suitable for water,diesel ,gasoline and kerosene and other light fuel,etc.

Special Surface Treatment

The whole valve body is passed a special surface process to improve the anti-corrosion.

Hydrodynamic Body

Design and high lift poppet minimizes pressure drop to give maximum flow rate.

External Shear Groove

Meets the standard requirements to limit product spillage in the event of an accident.

Manual Opening Device

When need to emergency discharging ,the pneumatic control is useless,it can be opened by manual way.

Easy-Installment

The size of the valve is more smart ,is suitable for the smaller space's demand.

Easy Servicing

Allows the air cylinder piston to be replaced without removing the valve from the tank pipe work.

Technical Specification

Technical Specification

| Product name | Emergency shut off valve/bottom loading valve |

| Normal Diameter | 3inch 4inch |

| Normal Pressure | 0.6Mpa |

| OpenWay | pneumatic |

| materials:aluminum | aluminum |

| Medium | diesel/gasoline |

| Working Temperature | -40℃-+70℃ |

Emergency Foot Valve

Size:80mm

Working Pressure:0.6Mpa

Power:Manual

Working Temperature:-20°C--+70°C

Medium:Water,Gas ,Oil etc

| Name | mm | Pressure | ||||||||

| D0 | D1 | D2 | D3 | H | H0 | Z-d0 | Z-d1 | b | ||

| Bottom Valve | Φ182 | Φ155 | Φ145 | Φ120 | 105 | 112 | 6-Φ14 | 6-Φ14 | 14 | 0.6Mpa |

Emergency shut-off valve,also known as bottom loading valve,installed the bottom of tankruck,which could be fueling download.

The operating principle is simple,the festival is safe and environmental protection.

Pressure balance type bottom loading valve for the multi position tanktruck,can be loading and unloading in separate oil .Three through the design of the pipeline,Relieve load,operation is simple,safe and reliable.

Internal pressure is small,large flow,valve flange with cutting groove in the tank,the Groove break can not carrying too much force,body pipeline and tank will automatically disconnect when the accident occurred,and automatic spring on the plunger and durable will remain sealed medium in the tank will not leak,so as to ensure the oil tank safety.the cylinder piston rod could be folded,manual way whe no gas source of the other reason can not be opened,in accordance with international standard GB/2002MT.

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD CHF

CHF HKD

HKD JPY

JPY RUB

RUB BRL

BRL CLP

CLP NOK

NOK DKK

DKK SEK

SEK KRW

KRW ILS

ILS MXN

MXN CNY

CNY SAR

SAR SGD

SGD NZD

NZD ARS

ARS INR

INR COP

COP AED

AED